Data & Analytics

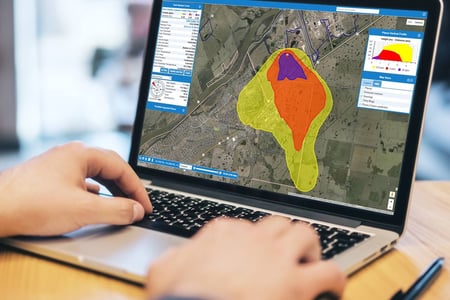

iNet Control+: The Air Traffic Control Tower of Safety Management

While waiting at the airport to board your flight for your next vacation or business trip, it isn’t often that you think about the air traffic...

Read More