Oxygen (O2) Gas Detectors

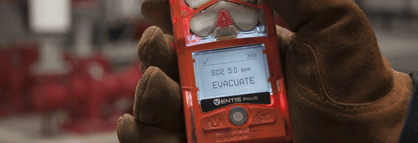

Accurate oxygen (O2) measurements are essential to prevent injuries or deaths in situations with potentially high or low levels of oxygen. O2 gas detectors will typically trigger an alarm when the oxygen level drops below 19.5 percent volume. The most common use of oxygen gas detection is in confined spaces—totally or partially closed areas not designed to be permanently occupied. It is essential to draw an O2 gas sample before entering these spaces and continuously monitor O2 levels after entry.

.webp?width=2000&name=confined-spaces-workers--%20(1).webp)

Characteristics of Oxygen

Oxygen is a gas without color, taste, or smell. While we breathe oxygen in the air, it is generally mixed with nitrogen. Oxygen displacement is a common result of many industrial processes, so it is important to measure oxygen levels and evacuate when the level drops below 19.5% volume, the OSHA-mandated level.

More about Oxygen

Effects of Various O2 Levels

Frequently Asked Questions

What is Oxygen (O2)?

Oxygen (O2) is a diatomic molecule consisting of two oxygen atoms. It is a colorless, odorless gas essential for the survival of most living organisms. Oxygen makes up about 21% of the Earth's atmosphere and is crucial for cellular respiration in humans, animals, and plants. It is also used in various industrial processes, including metal cutting and chemical production.

Why is Oxygen (O2) detection important?

Oxygen (O2) detection is vital for ensuring safety in environments where oxygen levels can fluctuate. Inadequate oxygen levels can lead to hypoxia, while excessive levels can cause oxygen toxicity. Monitoring oxygen levels is essential in industries such as healthcare, aerospace, and manufacturing to protect workers and maintain optimal operational conditions.

Can you be exposed to too much Oxygen (O2)?

Yes, exposure to excessively high levels of Oxygen (O2) can be harmful. Oxygen toxicity can occur when inhaling pure oxygen or high concentrations for extended periods. Symptoms include lung damage, vision disturbances, and seizures. It is crucial to regulate oxygen levels, especially in medical treatments and high-risk occupations, to prevent adverse health effects.

How do you detect Oxygen (O2)?

Oxygen (O2) is detected using various types of sensors, including electrochemical, zirconia, and optical sensors. Electrochemical sensors are common in portable gas detectors, providing real-time monitoring. Industrial Scientific offers a range of O2 detectors, including portable gas detectors and gas monitoring software systems.