Lately there have been a lot of questions about obtaining and using “pentane equivalent” calibration gas. So what is it?

The notion of “pentane equivalent” or “propane equivalent” gas was started by a manufacturer of gas monitoring instruments many years ago. It has been adopted by other manufacturers from time to time and has gained more traction in the market. So much so that end-users of combustible gas monitors are contacting calibration gas suppliers to ask for pentane equivalent gas. This is something that you just cannot do.

The premise is that you want to calibrate catalytic bead combustible gas sensors with pentane because you will get higher than actual concentration readings and a safe response when you are detecting other gases. The problem, however, is that if the sensor’s response to methane has diminished due to poisoning, you cannot see this with a pentane calibration.

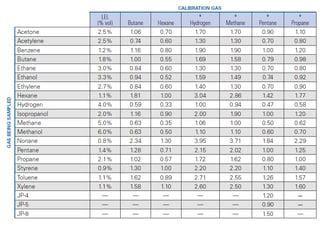

The pentane equivalent gas is a concentration of methane set to provide you the same response as a known concentration of 25% LEL and 50% LEL pentane. This correlation must be made based on the relative sensitivities of a new sensor to each gas. When done with a new sensor, it makes your calibration accuracy +/-25% at best.

Here is the rub as I see it. Calibration is supposed to set the response of the gas detector and the sensor to a known standard to establish the baseline accuracy of the readings. When you use the pentane equivalent gas, you are telling the instrument that you are calibrating to 25% LEL pentane when you are actually calibrating to some random concentration of methane. I say random because as the sensitivity to methane changes from the poisoning and the correlation between pentane and methane changes along with it, now you have no idea of the calibration standard and correlation. If you are calibrating to 25% LEL pentane, you are actually setting the instrument to that. If you are calibrating with 25 or 50% LEL methane you are setting the instrument to known standards. With so-called equivalent gases, you are relying on an unknown or changing correlation to establish a reference.

Although it is true that the sensor will be poisoned to methane and lose sensitivity to methane first, the initial relative sensitivity of methane to pentane is generally around 2:1, so there is a lot to lose. As a user, I don’t really care that the expected methane reading when you are calibrating to pentane should be 2:1. I only care that if I encounter methane, the instrument alarms and warns me accordingly. If the sensor has lost half of its sensitivity to methane, it is still going to give you the correct methane reading when calibrated to pentane. Now when you take into account that most LEL sensor alarm settings are 10% or even down to 5% LEL these days, even at a 50% LEL methane concentration, you have a 5 – 10 times safety factor in place on top of the pentane calibration.

Along with this, in more than 25 years of working with combustible gas monitoring instruments, I have yet to see a sensor so severely and naturally poisoned that it would not respond to methane at all and still provided even close to a normal pentane reading. If the sensor is that severely poisoned, there will be a significant loss of pentane sensitivity as well, which will be seen in reduced pentane full span readings during calibration.

Alternative Solutions

While it is undoubtedly true that using a pentane equivalent or propane equivalent calibration gas will help you recognize that a sensor has been poisoned to methane, there are other ways to accomplish this. You may choose to calibrate your sensor to pentane to set an accurate reference and bump test the same sensors before use with methane to check for poisoning.

Industrial Scientific has a better solution to this problem in the MX6 iBrid® multi-gas monitor. The MX6 allows you to set and establish the calibration gas to methane and then select and automatically apply a response factor for pentane to the readings. This gives you the best of both worlds! You can calibrate, establish accuracy and detect poisoning to methane in the sensor’s full span readings. You can also have enhanced reading response using the pentane correlation factor as if the sensor was calibrated to pentane. As the sensor loses sensitivity to methane, the pentane-correlated readings become more pronounced.

Outside of the MX6, Industrial Scientific’s recommendation for calibrating combustible gas sensors remains as it always has been. If you know the target gas you will be detecting, calibrate the sensor to a known concentration of that gas. If you are using the sensor for general combustible gas detection, calibrate to a known concentration of pentane.

In the end, you need to determine what is most important to you. If you are using your sensors in areas where known sensor poisons are prevalent, you should probably bite the bullet and calibrate your sensors regularly with methane. You will be able to detect the effects of the poisoning and still establish your readings based on a known and consistent standard. If poisoning is only a minor issue and having an accurate basis for your readings is a priority for you, continue to calibrate with pentane and forget about the notion of equivalent gases.