In today's rapidly evolving industrial landscape, the importance of leveraging gas detection data to inform safety programs cannot be overstated. With the proliferation of real-time data usage and predictive models, the role of the Internet of Things (IoT) in revolutionizing safety protocols has become increasingly significant. By utilizing these advanced technologies, organizations can create safer work environments and enhance operational efficiency.

In today's rapidly evolving industrial landscape, the importance of leveraging gas detection data to inform safety programs cannot be overstated. With the proliferation of real-time data usage and predictive models, the role of the Internet of Things (IoT) in revolutionizing safety protocols has become increasingly significant. By utilizing these advanced technologies, organizations can create safer work environments and enhance operational efficiency.

Top Ways to Use Gas Detection Data to Improve Safety

Gas alarms serve as early indicators of potential danger, providing critical data on worker exposure to hazardous gases. For instance, when a high gas alarm sounds, it prompts workers to evacuate the area, triggering a follow-up procedure by safety managers. Utilizing data gathered by personal gas detectors, managers can make informed decisions about sending exposed workers for medical examinations, even if they initially feel fine. This proactive approach ensures that even short exposures to high concentrations of gases are addressed promptly, potentially saving lives.

Despite advancements in gas detection technology, improper usage of instruments remains a significant risk. Data from gas detectors can identify at-risk behaviors, such as using detectors without bump tests, ignoring alarm events, or failing to use detectors altogether. By analyzing this data, safety managers can implement corrective measures to ensure compliance and proper equipment usage, ultimately reducing the likelihood of injuries or fatalities.

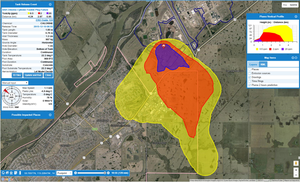

Historical alarm data can reveal patterns and trends, helping organizations identify the root causes of recurring issues. For example, if multiple alarms are triggered at a specific location over time, this data can highlight a potential gas leak or hazard. By addressing these patterns, organizations can prevent future incidents, saving time, money, and most importantly, protecting workers from ongoing hazards.

Four Key Elements of a Data-Centric Safety Program

-

Collecting the Right Data at the Right Time

Collecting the Right Data at the Right Time

Transitioning from paper-based reports to cloud-connected systems streamlines the process of gathering critical data. Cloud-connected docking stations and real-time sensors automate data collection, making it easier to access and use this information for future safety decisions. - Predicting and Preventing Future Incidents

Combining gas alarm data with safety observations allows organizations to uncover trends and root causes. For instance, addressing behaviors that trigger gas hazards can prevent unsafe actions and improve overall safety. By using data to predict and prevent incidents, organizations can create safer work environments. - Automating Equipment Maintenance and Replacements

Tracking sensor health, battery levels, and calibration gas status ensures that gas monitors remain in optimal condition. Automated alerts for maintenance and replacements help prevent downtime and equipment failure, ensuring continuous protection for workers. - Viewing the Whole Safety Picture

Integrating gas detection data with other safety insights provides a comprehensive view of workplace safety. By analyzing data from multiple sources, organizations can make better-informed decisions, improving processes and safety practices across worksites.

Overcoming Common Challenges in Gas Monitor Safety Programs

Human Error and Alarm Fatigue: Frequent alarms can desensitize workers, leading them to ignore or shut off monitors. Safety management must proactively monitor behaviors to address this issue. Ensuring that workers understand the importance of gas alarms and adhere to safety protocols is crucial for maintaining a safe work environment.

Human Error and Alarm Fatigue: Frequent alarms can desensitize workers, leading them to ignore or shut off monitors. Safety management must proactively monitor behaviors to address this issue. Ensuring that workers understand the importance of gas alarms and adhere to safety protocols is crucial for maintaining a safe work environment.

Maintaining Compliance with Calibration and Testing: Automating reminders for bump tests and sensor replacements helps ensure consistent safety practices. By maintaining regular calibration and testing, organizations can uphold compliance standards and protect workers across shifts and locations.

Navigating Complex Work Environments: For mobile workers, using Bluetooth and NFC tags simplifies the assignment of gas monitors. Tools like iAssign® Technology enable precise tracking of workers and equipment, ensuring that safety protocols are followed regardless of location.

Practical Tips for Managing Gas Detection Data Efficiently

Using Software Tools for Better Visibility and Actionable Insights: Assigning usernames and locations to connected devices streamlines data management. Creating customized reports simplifies data analysis, allowing safety managers to act on insights promptly.

Leveraging Data to Manage Exposure Risks: Tracing gas alarms back to individuals and locations helps develop targeted safety protocols. By understanding the history of hazards, organizations can implement measures to mitigate risks and protect workers effectively.

Role of Predictive Analytics in the Future of Gas Monitor Safety Programs

Using historical data and trend analysis, AI and predictive models can forecast gas leaks and other hazards. This proactive approach allows organizations to address potential issues before they become critical, enhancing safety and efficiency.

Bluetooth beacons and NFC tags can also enable precise tracking of workers, providing real-time data on their locations and activities. IoT-driven monitoring enhances safety by ensuring that workers are protected at all times.

Embrace Data to Build a Robust Gas Monitor Safety Program

In conclusion, data is key to reducing risks and improving safety outcomes. By investing in connected devices and data analysis tools, organizations can optimize their safety operations and create safer work environments. Embrace the power of data to build a robust gas monitor safety program and protect your most valuable asset – your people.